Double 85 Constant Temperature And Humidity Reliability Environmental Test (THB)

First, high temperature and humidity test

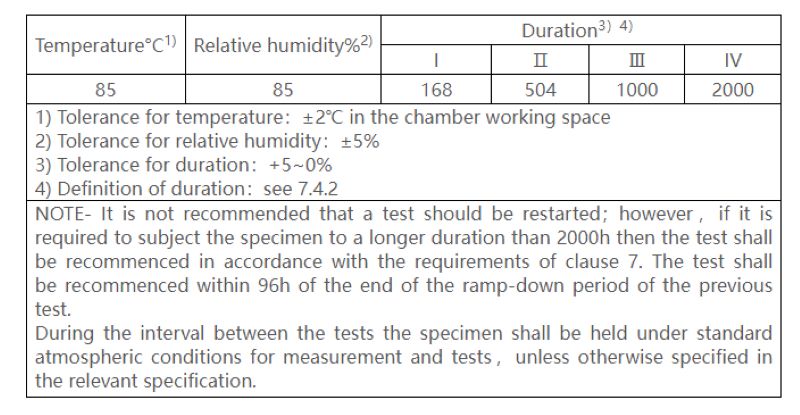

WHTOL (Wet High Temperature Operating Life) is a common environmental stress acceleration test, usually 85℃ and 85% relative humidity, which is generally carried out in accordance with the standard IEC 60068-2-67-2019. The test conditions are shown in the chart.

Second, the test principle

"Double 85 test" is one of the reliability environmental tests, mainly used for constant temperature and humidity box, that is, the temperature of the box is set to 85℃, the relative humidity is set to 85%RH conditions, to accelerate the aging of the test product. Although the test process is simple, the test is an important method to evaluate many characteristics of the test product, so it has become an indispensable reliability environmental test condition in various industries.

After aging the product under the condition of 85℃/85%RH, compare the performance changes of the product before and after aging, such as the photoelectric performance parameters of the lamp, the mechanical properties of the material, yellow index, etc., the smaller the difference, the better, so as to test the heat and moisture resistance of the product.

The product may have thermal failure when working in a continuous high temperature environment, and some moisture sensitive devices will fail in a high humidity environment. The dual 85 test can test the thermal stress generated by the product under high humidity and its ability to resist long-term moisture penetration. For example, the frequent failure of various products in the humid weather period in the south is mainly due to the poor temperature and humidity resistance of the products.

3. Experimental factors

In the LED lighting industry, many manufacturers have used the double 85 test results as an important means to judge the quality of lamps. Various possible reasons why LED lamps fail the dual 85 test are:

1. Lamp power supply: poor heat resistance of shell, danger of short circuit in circuit, failure of protection mechanism, etc.

2. Lamp structure: unreasonable design of heat dissipation body, installation problems, materials are not resistant to high temperature.

3. Lamp light source: poor moisture resistance, packaging adhesive aging, high temperature resistance.

If you encounter a special use environment, such as the working environment temperature is severe, you need to test its high and low temperature resistance, the test method can refer to the high and low temperature test project.

4. Serve customers

01. Customer group

LED lighting factory, LED power plant, LED packaging factory

02. Means of detection

Constant temperature and humidity test chamber

03. Reference standards

Constant temperature and humidity tests for electrical and electronic products -- Environmental testing -- Part 2: Test methods -- Test Cab: Constant temperature and humidity test GB/T 2423.3-2006.

04. Service content

4.1 Refer to the standard, conduct double 85 test on the product, and provide the third party's test results report.

4.2 Provide the analysis and improvement plan of the product through the double 85 test.