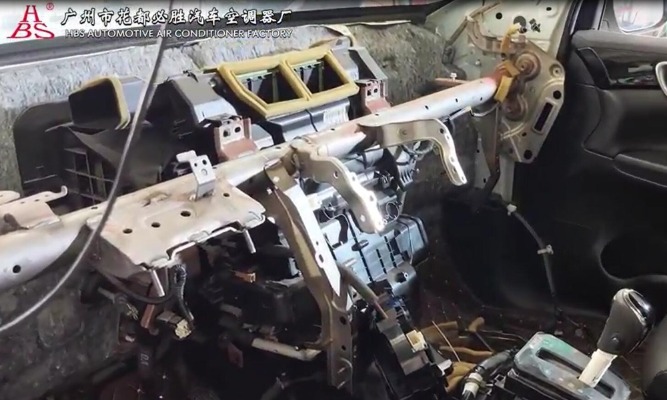

The steps to replace a condenser are as follows:

Preparation: First, ensure that the power is turned off and wear protective gloves and goggles to avoid the risk of electric shock. Prepare the necessary tools and materials, including wrenches, screwdrivers, pliers, sealant, a new condenser, and coolant.

Remove the old condenser: Turn off the power and cooling system, drain the coolant, and then remove the connecting pipes and mounting fixtures. When disassembling, pay attention to marking the connection positions of each pipeline for future installation.

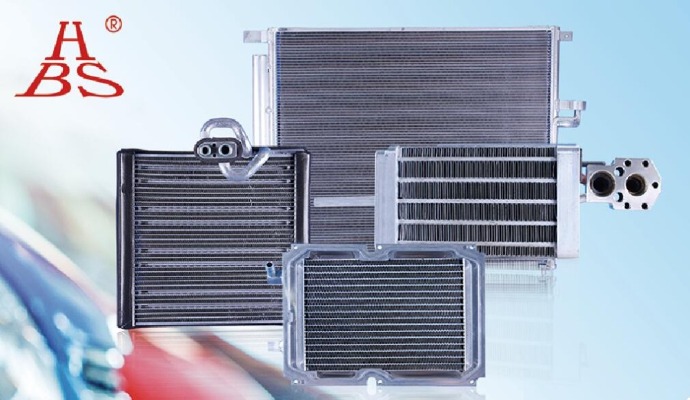

Install the new condenser: Position the new condenser in place and secure it using screws or brackets. When connecting the pipes, ensure that the joints are tight and gap-free, and use sealant to further enhance the sealing. When injecting refrigerant, follow the system requirements and pay attention to the fill amount and speed to avoid excessive or insufficient filling.

Test and adjust: Connect the power and start the equipment, observe the operation and cooling effect of the condenser. According to the equipment manual, make reasonable adjustments to the refrigeration system parameters to ensure the proper operation of the condenser.

Leakage check: Perform a thorough leak check before starting the equipment to ensure that all connections are leak-free.

Record and maintenance: Keep detailed records of the condenser replacement time and relevant data for future maintenance and inspection work. Regular inspections and maintenance should be conducted after replacement to ensure stable equipment operation.

Common causes of condenser failure include dirt accumulation, material corrosion, coolant leakage, and mechanical damage. These factors can reduce the heat dissipation efficiency of the condenser and affect the overall performance of the refrigeration system. Therefore, regular maintenance and timely replacement of faulty condensers are crucial for ensuring efficient equipment operation.