Vacuum Chamber-Type Helium Leak Detection Equipment is an advanced leak detection device that is based on helium mass spectrometry leak detection technology. It is specifically designed to detect minute leaks in various components or systems. The following is a detailed description of this equipment:

Equipment Structure

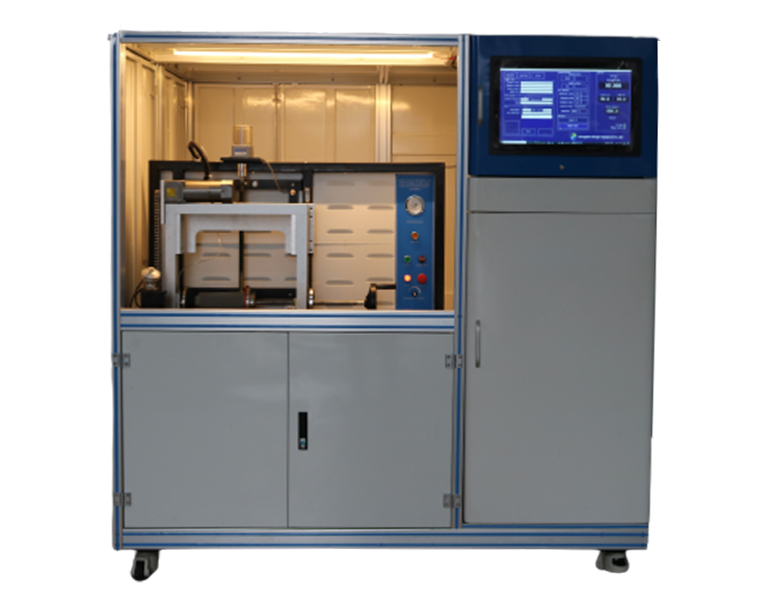

The equipment mainly consists of a vacuum box, a vacuum pumping system, a helium charging system, a helium mass spectrometry leak detector, and a control system.

Vacuum Chamber: A sealed container used to place the test piece. A high vacuum environment can be created inside the vacuum chamber to facilitate the detection of minute leaks.

Vacuum Pumping System: Includes a vacuum pump and related piping and valves, used to extract air from the vacuum chamber to achieve the required vacuum level.

Helium Charging System: Used to introduce a certain amount of helium gas into the test piece or vacuum chamber. Helium is an inert gas with small molecules that can easily penetrate through minute leak holes.

Helium Mass Spectrometry Leak Detector: The core component of the equipment, used to detect the amount of helium gas leaking from the test piece. It utilizes the principle of mass spectrometry to detect the presence of helium with high sensitivity.

Control System: Used to control the operation of the equipment, including automated control of vacuum pumping, helium charging, and detection steps.

Working Principle

Place the test piece inside the vacuum chamber and close the sealed door of the vacuum chamber.

Activate the vacuum pumping system to extract air from the vacuum box and achieve a certain vacuum level.

Introduce a certain amount of helium gas into the test piece or vacuum chamber through the helium charging system.

Activate the helium mass spectrometry leak detector to start detecting the amount of helium gas leaking from the test piece.

Judge the leakage situation of the test piece based on the detection results of the helium mass spectrometry leak detector.

Equipment Features

High Precision: Adopts advanced helium mass spectrometry leak detection technology, capable of accurately measuring the leak rate of the test piece with small errors.

High Efficiency: The equipment has a high degree of automation, simple and quick operation, and can rapidly complete leak detection tasks.

Safe and Reliable: The equipment is designed reasonably, equipped with various safety protection measures, and can ensure the safety of operators.

Wide Application Range: Suitable for test pieces of various shapes and sizes, widely used in electrical, electronic, aerospace, communication, chemical, and other industries.

Applications

Vacuum Chamber-Type Helium Leak Detection Equipment has a wide range of applications in multiple fields, such as:

Aerospace: Used to detect leaks in aerospace equipment such as airplanes and rockets, ensuring flight safety.

Electrical and Electronic: Used to detect leaks in electrical and electronic products such as electronic components and circuit boards, ensuring product quality.

Communication: Used to detect the sealing performance of communication equipment, ensuring the stability and reliability of equipment in harsh environments.

Chemical: Used to detect leaks in chemical equipment, preventing the leakage of harmful substances from causing environmental pollution.

In summary, Vacuum Chamber-Type Helium Leak Detection Equipment is a high-precision, high-efficiency, safe, and reliable leak detection device with broad application prospects and market value.